New AS250-10 Hydraulic Shear

New AS250-10 Hydraulic Shear

Contact us for price

Location:Little Rock, AR

or

Call 1 501-897-1110

Description

All Components Readily Available From Your Local Suppliers

Precision Guillotine Drive Providing the Best Shearing System Available

36″ travel PLC backgauge w/Go-To function & multi-job programming

Infinitely Variable, Manual, Quick-Change Blade Gap Adjustment

80,000 PSI Capacity rated

Manual Swing-Away Backstop

5 Year Parts Warranty

5 Year limited onsite labor warranty

Lifetime telephone support at no charge

4′ squaring arm with scale

Standard Features

Standard Features

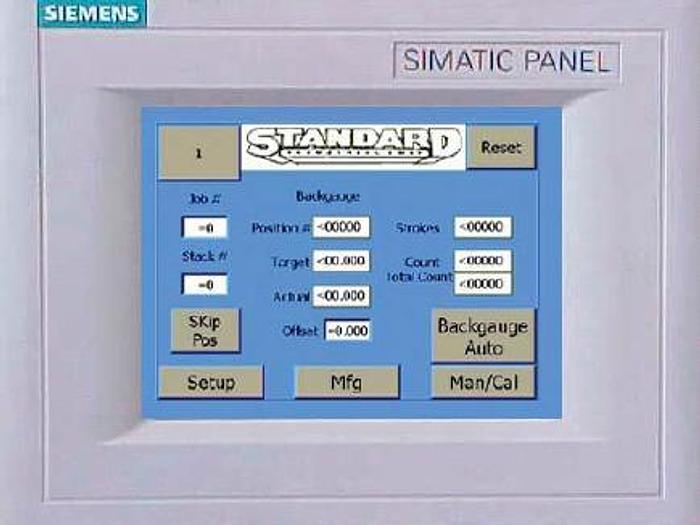

PLC Touch Screen Control

Simple Go-To function

50 job programmability with 5 cut lengths per job

Automatic actuation of backstop during program

5 programmable cut lengths per job

Stack your jobs up to any number of strokes

Inch/Metric conversion and Stroke Counter

Programmable X (backstop) retract

2 year PLC and interface warranty

Manual and programmable functions

Swiveling pendant mount for easy operation

PLC Touch Screen Control

Simple Go-To function

50 job programmability with 5 cut lengths per job

Automatic actuation of backstop during program

5 programmable cut lengths per job

Stack your jobs up to any number of strokes

Inch/Metric conversion and Stroke Counter

Programmable X (backstop) retract

2 year PLC and interface warranty

Manual and programmable functions

Swiveling pendant mount for easy operation

PLC Touch Screen Control

Simple Go-To function

50 job programmability with 5 cut lengths per job

Automatic actuation of backstop during program

5 programmable cut lengths per job

Stack your jobs up to any number of strokes

Inch/Metric conversion and Stroke Counter

Programmable X (backstop) retract

2 year PLC and interface warranty

Manual and programmable functions

Swiveling pendant mount for easy operation

Simple Go-To function

50 job programmability with 5 cut lengths per job

Automatic actuation of backstop during program

5 programmable cut lengths per job

Stack your jobs up to any number of strokes

Inch/Metric conversion and Stroke Counter

Programmable X (backstop) retract

2 year PLC and interface warranty

Manual and programmable functions

Swiveling pendant mount for easy operation

No other backgauge comes close to the rigidity coupled with the brute strength of the Standard Industrial shear backgauge. Perfectly built for precision and outright ability to take abuse.

All Standard shears come equipped with our positive drive, mechanical, quick-change blade gap adjustment. The AS250-6 up through the AS375-12 models are equipped with our Infinitely Variable side adjustable manual system.

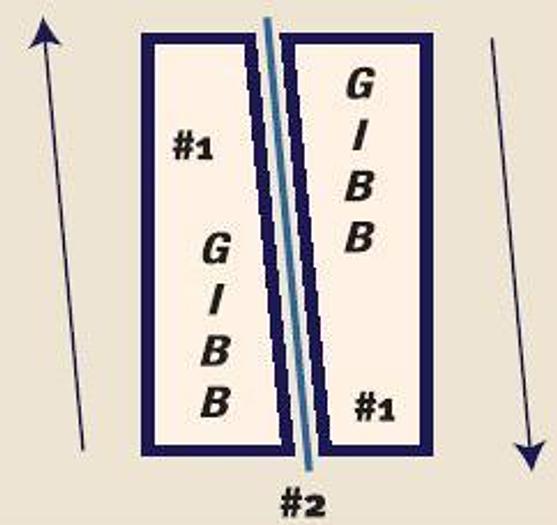

The 14′ and longer and all 1/2″ and larger shears are equipped with the Infinitely Variable front operated Power blade gap system. Uniform and precision movement along machined tapered gibbs allows you to zero in on an exact precision cut.

On each end of the shear ram is our Extremely Heavy-Duty Gibbing system. This positive mechanical system provides a smooth, uniform gap adjustment via precision machined tapered gibbs. Each gibb plate (#1) slides opposite of each other on oil impregnated nylon called Nylatron (#2). This Nylatron insures no excessive heat or friction is built up. These gibbs also control the front to back and left to right forces of the ram travel delivering the most precision cut available on any shear.

SPECIFICATIONS AND CONDITION ARE CORRECT TO THE BEST OF OUR KNOWLEDGE AND ARE SUBJECT TO YOUR VERIFICATION AND CORRECTION. THE CONDITION OF THE MACHINE IS AS IT HAS BEEN REPRESENTED TO US. ALL MACHINES ARE SUBJECT TO PRIOR SALE. EVERY MACHINE, UNLESS OTHERWISE SPECIFIED, IS OFFERED SUBJECT TO OUR GUARANTEE THAT IF FOUND TO BE MECHANICALLY UNSATISFACTORY WITHIN 30 DAYS AFTER SHIPMENT, SAME MY BE RETURNED, FREIGHT PREPAID FOR FULL CREDIT OR REPAIRED AT DEALER’S OPTION. ALL MACHINES RETURNED TO US MUST BE IN AS GOOD A CONDITION AS WHEN SHIPPED.

Specifications

| Model | AS250-10 |

| Condition | New |

| Capacity to mild steel/a36 | 1/4" x 10' |

| Capacity of stainless steel | 10ga x 10' |

| Shearing tons | 36 |

| # of hold downs | 11 |

| Bore of hold downs | 2" |

| Hold down force | 31 Tons |

| Weight | 19,000 lbs |

| Backgauge travel | 36" |